Read time: 3 mins

Date posted: Jan 2018

Theme: Electrification, Product Innovations

The future of Research and Development in Powder Metallurgy

"It will be our task in the innovation team to identify new applications for our PM technology that result from the HEV & EV transition and any other electrified applications beyond the automotive sector."

This is the mission GKN´s Dr. Nils Bornemann highlighted as we spoke with him about GKN´s Research and Development (R&D) structure, the Advanced Engineering team's key projects for 2018 and the progression of disruptive changes and shortened development cycles.

Q: Nils, your current role is Vice President of Advanced Technology. Can you give us a short introduction to your team and responsibilities?

Our Advanced Technology and Processes team is core to our innovation strategy. In my role, I lead a team of about 60 experienced scientists and engineers based at our innovation centers in Radevormwald (Germany) and Auburn Hills, Michigan (USA). It's our task to find more sustainable product solutions through our PM technology for automotive and industrial applications. Our focus is on new technical solutions that go beyond the design capabilities of the engineering teams in our customer-facing operations.

Q: Is there any specific focus on markets or applications within this R&D group?

Our internal organization builds around applications and components where PM technology can offer a premium advantage in functionality or sustainability. Our current structure might have developed around our strong automotive footprint; however, we actively work on projects in a variety of markets, with needs in:

- Advanced Gear technology

- Soft Magnetic applications

- Aluminum applications

- Metal hydride based hydrogen storage

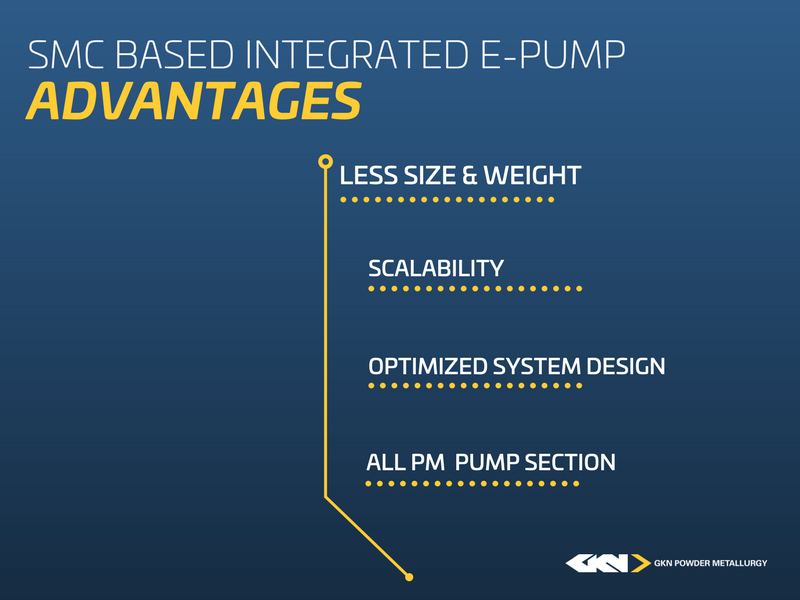

Looking ahead, there is one important topic dominating the agenda, and that is electrification. Hybrid and full electric vehicles drive new requirements, and our Advanced Gears team focuses on opportunities to build compact and lightweight e-pumps and e-motors with soft magnetics. Even our hydrogen storage activities are driving an 'electric' story.

Read more on our expertise in electric pumps here.

Q: You want to establish an own team for simulation technology - why is that?

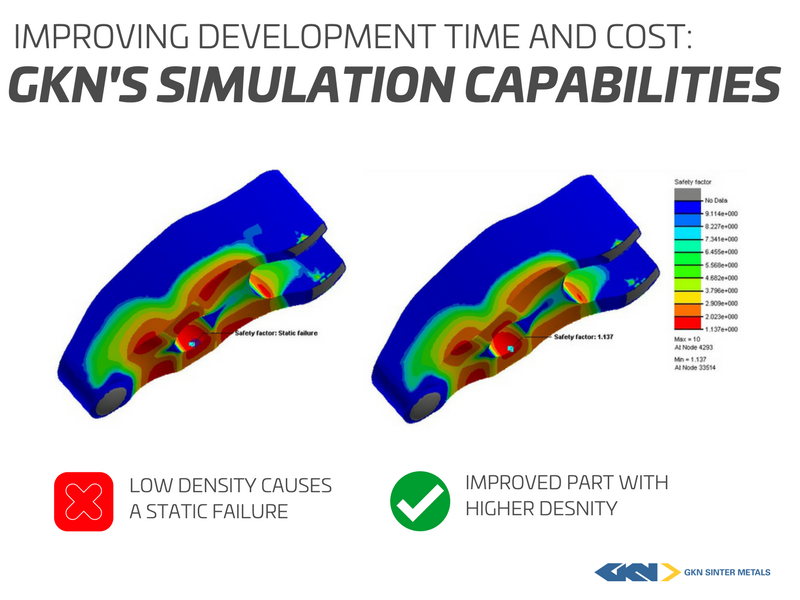

GKN is already using simulation methods and software tools and we have seen great benefits, especially working together with our customers at an early stage of development. Being able to simulate the performance of design alternatives in advance of prototyping and bench testing allows a much earlier evaluation of promising ideas. We believe the simulation technology has strong benefits to accelerate TRL (Technical Readiness Level) and MRL (Manufacturing Readiness Level) KPIs for many innovation projects.

Q: You mentioned the one overarching topic is electrification. Where do you see the greatest advantages of PM technology here?

Our Soft Magnetic technology will make a difference in future designs for compact e-pumps and e-motors, especially in mobile applications. To achieve acceptable performances for range and charging times of HEVs and EVs, it is key to ensure the best efficiency of any electric system and to save weight. This is one of the sweet spots of our soft magnetics, with unrivalled compaction and functional integration. This combined with the near net shape design capability is one of the key advantages of our PM technology.

This is similar to our efforts in aluminum PM, where the advantage on weight reductions is extremely noticeable. The additional benefit lies in the thermal conductivity properties that combine mechanical functionality with cooling capabilities for inbuilt heat management, all which supports the overall objectives to reduce CO2 and NOX emissions.

Evaluating optimal material, density, and post-processing combinations are typical applications that are highly valued by our customers within the development process.

Q: Does the trend toward shorter innovation cycles and lead times impact the way GKN manages R&D capacities?

Acceleration is one aspect, and a broader strategic focus is the other. Historically GKN has been focused on the automotive segment. As we now expand and leverage our capabilities to other industrial markets, we now become more focused in the way we manage our R&D. We will establish a stricter approach to review projects earlier and more accordingly, resulting in result-oriented mindsets. The investment in better digital resources and simulation tools will support this.

I'm also very keen to embark on more research partnerships with universities and research institutions. I've seen this as a valuable way for mutual exchange of knowledge, inspiration and will help us get to know future talents for our team.

With the idea to accelerate system development cycles, we have started development partnerships with customers, giving us the opportunity to take a more holistic approach and responsibility for the development of an entire system. This way we can better utilize the capabilities of the PM technology in terms of functional integration and lightweight solutions.

We strive to be the one-stop solutions partner for metal shaped solutions. It's a key task of our R&D to explore opportunities where our technology provides a solution to challenges in any application, from automotive or industrial electrification and beyond.

Interested in learning more about our Advanced Engineering Team's capabilities? Connect with Nils here: