Read time: 1 min

Date posted: Jun 2019

Theme: Product Innovations

GKN's Park Range Sensor Control Bracket showcases PM's net-shape advantages

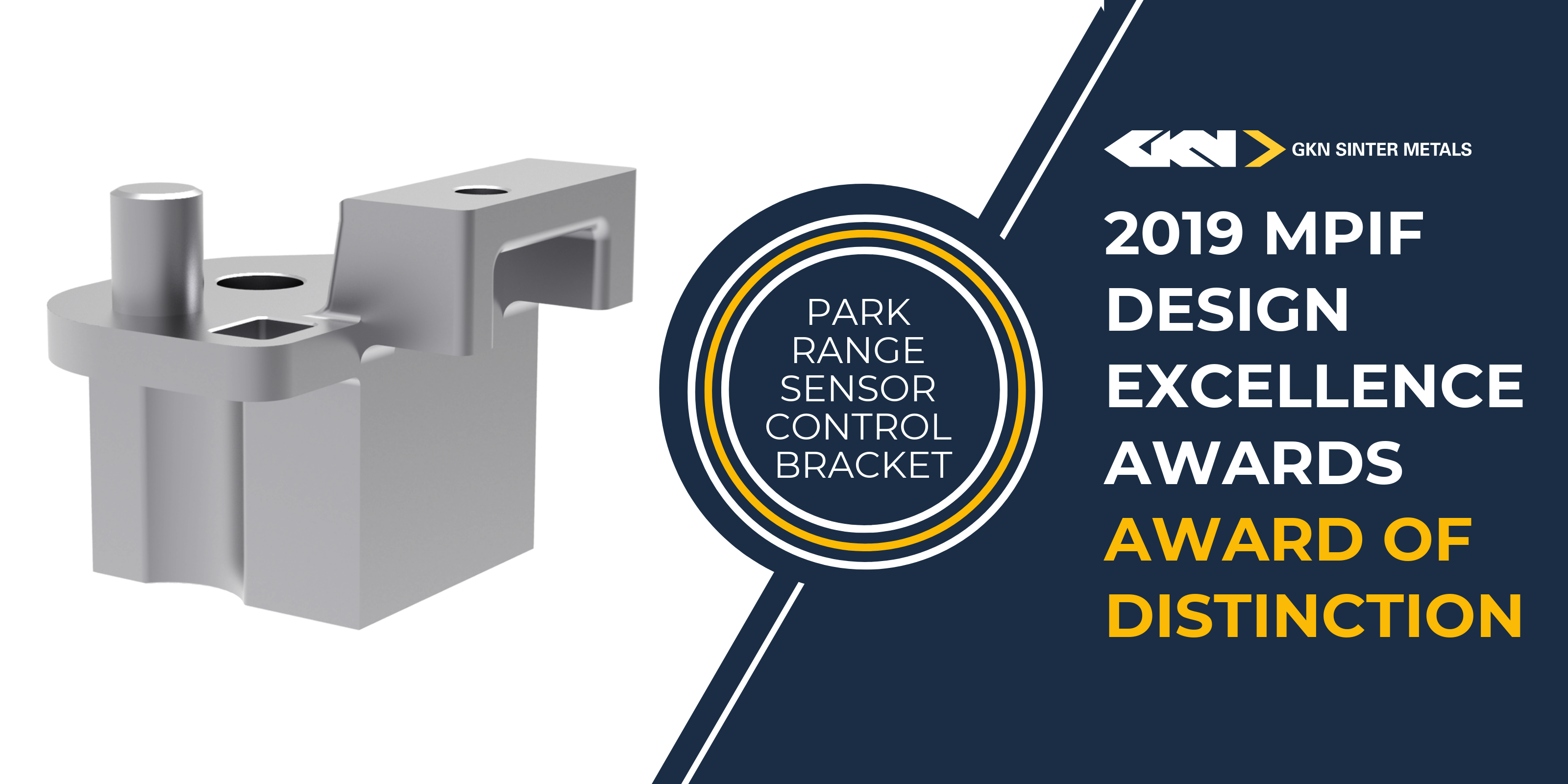

Recognized for its exceptional design concept, GKN’s Transmission Park Range Sensor Control Bracket has earned the Award of Distinction during the Metal Powder Industry Federation (MPIF)’s Design Excellence Awards ceremony.

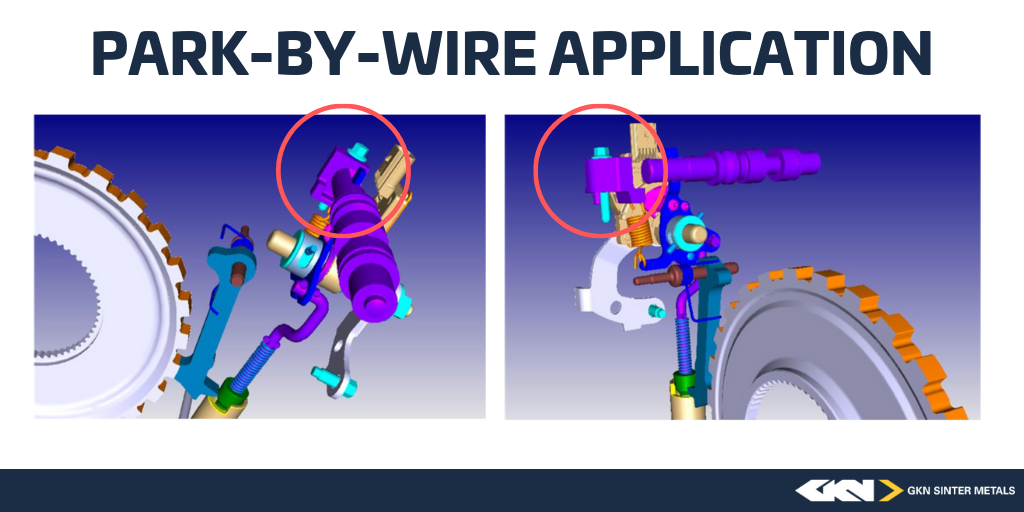

The bracket acts as a stopping block to prevent the over-travel of the transmission control rod in an automatic transmission park system. Utilizing GKN’s manufacturing capabilities in advanced press technology resulted in achieving the PM advantage of net-shape forming, eliminating the need for secondary operations.

The Challenge

Originally designed for a casting process, the sensor control bracket required additional machining which resulted in a higher overall cost. While the casting process could produce the complicated shape, surfaces would still need to be machined to meet tolerance requirements.

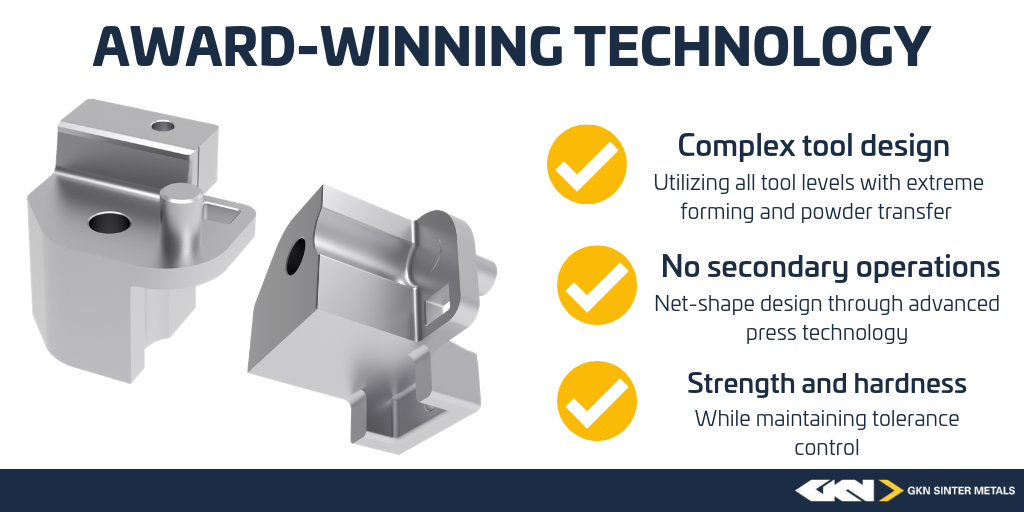

The component’s difficult design challenged GKN’s tool experts to create a robust tool design, which could be reliably pressed at production volume levels of one million pieces annually. The final design required five lower and three upper independent tooling levels, utilizing the full capabilities of GKN’s advanced CNC press technology.

The Result

The PM bracket is a net-shape product with a greater tolerance control at a lower cost compared to competing processes. No secondary operations are required.

FLC2-4808-85HT, the sinter-hardened material chosen for the component, provides the strength and hardness needed for performance while maintaining the required tolerance control.

GKN’s creative PM design proposal demanded the utilization of advanced CNC press technology with the capability to support the required amount of tooling levels needed for a robust compaction process. The CNC compaction process allows for complex designs with extreme forming and powder transfer capabilities, resulting in the creation of PM components previously not possible without secondary machining.

Why PM?

PM technology provides the greatest opportunity to design a net-shape component with no additional secondary operations, resulting in a lower cost while maintaining high performance, exemplified here with the award-winning Transmission Park Range Sensor Control Bracket.

Through collaboration, GKN’s team of experienced designers and engineers provide the necessary support in potential product conversion opportunities that may require non-conventional designs and processes. This component showcases PM’s ability to provide a higher performance and lower cost alternative to more traditional metal working processes.